Part of this material I used in the 20 hour granite course I taught at Pratt. Most of the info is from Tom Urban's workshop at Camp Brotherhod, some from a workshop by Don Ramey that Hank Nelson organized at my place years ago. If you find anything useful, please add it to the article - Kirk

Pneumatic hammers

Sources:

Types:

- D (Dallet) long stroke 3/4 “, 1 inch. Used for removing lots of stone. More impact, vibration.

- B short stroke 1/2, 3/4, 1 inch. Less vibration, used for detail.

- Bantam-fine detail, lettering

- Many carvers use 3/4D, control impact by amount of air.

Air consumption:

- 4 CFM-1/2 & 3/4;

- 6 CFM-1”

- For 1" hammer a whip connection (see photo)is recommended so as not to beat up the coupler. It is likely that once you put a whip on one then you'll find yourself putting them on all.

- Control air flow to hammer with an adjustable valve (stop cock). Note valve handle is small enough so as to not get caught on everything yet big enough to easily turn it without fumbling.

Chisel diameter:

- B & D take 1/2” shank,

- Bantam smaller. Many European chisels fit Bantam.

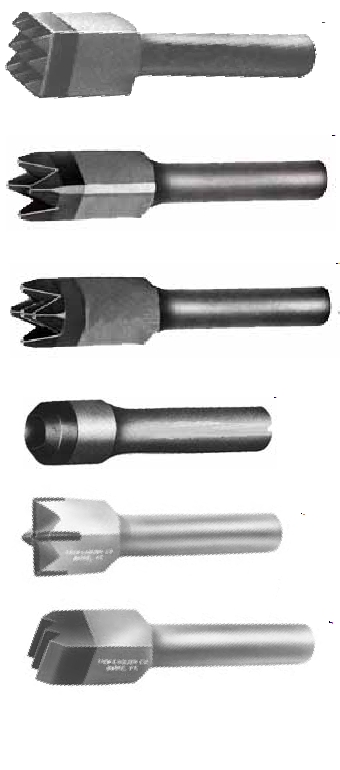

- 4 pt square or 5pt round: stone removal

- 9 pt: stone removal, final shaping

- cup, criss-cross, axe: finish.

- Rippers, long 4 pt: Deeper carving. NOT used like toothed chisel.

- Criss-cross for cleaning up frets

Carving chisels:

- roughing have heavy profile, finishing a bit thinner.

- Limestone thinner and wide

- Granite requires carbide blade set into steel.

- Avoid wedge insert (marble blade), tends to pop out.

- DO NOT pry on chisel, let it do work.

Safety: Vibration, noise, dust & chips.

- Usual eye, hearing and breathing protection.

- Wear padded gloves, grip gently.

- DO NOT grip tightly, lean into stone.

- Take frequent breaks from work.

Air hammer care:

- If sticking soak in kerosene overnight.

- Or, add WD-40, run, then put in white spindle oil (10 SAE).

- Oil hammers before and after use.

- Run at low speed for minute before putting under load.

- Running hammer full speed without chisel can damage it.