Some thoughts on diamond blades

If you only get one.....

which one will do you the most good?

For the sake of clarity, let's just talk about what you could get that would be most useful with any small electric grinder, rated for 4 1/2" or 5" blades, single speed, for a mix of hard and soft stones. I will try to offer my reasons for choosing one of the many kinds of diamond blades available, based on what different chores it can do, how versatile it is, and how affordable it is.

I will talk about the different kinds of diamond blades, what each is best at, etc. First we must acknowledge that none of them were designed for carving. We are a tiny fringe market, and we use tools that were made for construction and industry. Most of the work we do with diamond blades is on the manufacturers' DON'T DO THIS list, which just means we have to be cautious and not push the blades too hard.

I will talk about the different kinds of diamond blades, what each is best at, etc. First we must acknowledge that none of them were designed for carving. We are a tiny fringe market, and we use tools that were made for construction and industry. Most of the work we do with diamond blades is on the manufacturers' DON'T DO THIS list, which just means we have to be cautious and not push the blades too hard.

But there are qualities we can look for, and recognizing the ways these things are made can be useful. Basically there are 3 methods of attaching the diamonds: plating, brazing, and sintering.

Plating electrochemically coats the steel blade with a thin layer of diamonds, usually a fairly fine grit. In my opinion, we wear these out too fast to get much use out of them. Tile cutting is ok.

Brazing is similar, in that it binds a coating of diamonds to the surface of the steel blade, but it is generally much tougher. A good brazed blade has a deeper layer, of coarser grit, than plated blades, and they don't wear off nearly as fast. The kind of stone makes a big difference, however. I restrict mine to a diet of marble or softer, for which they are great. If you are not carving much hard stone, this might be your choice. They come in regular or flush mount configurations, and segmented or continous rim. They vary some in cost, but most are cheaper than sintered blades. I haven't tried enough to have a preference in brand name, so maybe somebody else can make a recommendation there.

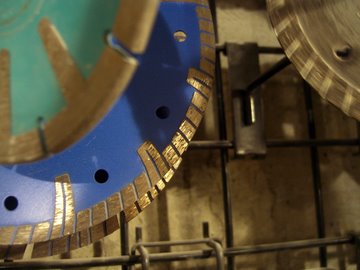

Sintered blades are what I use most, and they come in a variety of forms, too. In the picture above, the one on the right is a turbo, the left one is segmented, and in the middle is a combination. The sintering process embeds the diamond chips within a matrix of metal, which is thicker than the blade itself, and as it wears down, more diamonds are exposed. Long life is the benefit. The trick to getting the most out of these blades is to keep them cool, because the friction of continuous grinding will heat them up enough to glaze the matrix, or the diamonds, or both. They just stop cutting, and start throwing sparks and molten stuff, the blade warps, and can also crack. In a cheap blade, with just the slightest excess of pressure, this can happen in minutes, and can't be fixed. The better blades seem to be more tolerant, but even the best can be ruined by pushing too hard, or keeping the cut going too long or deep.

If you carve wet, you can be much rougher on your blades. If not, there are a few tricks to prolonging blade life. One is short bursts of cutting, with frequent breaks. Just hold the tool off the stone for a minute, leave it running, and it will cool down. I even give it a minute-long blast of compressed air while it is running free. Another is George Pratt's idea: touch the edge of the moving blade across a moving bench grinder wheel to freshen the blade, whenever it feels sluggish. * This technique, of course, is only for sintered blades. It would quickly ruin a plated or brazed blade. Most important is to keep the fret kerfs short, and apply no more force than the weight of the grinder. Now I have digressed beyond the choice I was about to offer, I hope you don't mind.

My do-it-all blade would be a 4 1/2" flushcutting turbo. I like Pearl gold, and have had fair success with Talon, which cost about half as much, but wouldn't go any cheaper. Of course the flushcut doesn't fit inside the guard so well, but that's another discussion. It will cut any marble, will gobble up limestone and alabaster, and will carve well in most granites and basalts.

These are my opinions only, and I welcome being corrected by other carvers with more experience and knowledge. I hope this exercise is useful to you. Tracy Powell 01/01/10