After expending the effort to drill a mounting hole perpendicular to a base or to the bottom of a sculpture there remains the problem of keeping the pin or sleeve correctly aligned as the epoxy cures. Fast curing epoxies often don’t allow enough positioning time and slow cures try patience, as well as muscle control, if you attempt to hand hold the fixture while continually checking alignment with a square.

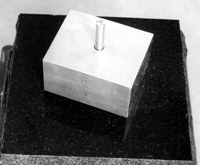

I have constructed several jigs by using a drill press to drill guide holes for various pin sizes in blocks of wood and metal. The jig illustrated is an aluminum block with a 1/2 inch guide hole and a shallow, larger diameter hole on the underside to provide a cavity for the nearly inevitable epoxy squeeze-ups that could glue the jig to the work. Dry fitting all of the pieces without epoxy to check the accuracy of the hole is advisable. After partially filling the hole with epoxy and inserting the pin, or sleeve with a pin, I clean off the excess epoxy and place the jig over the protruding pin, moving it about until the jig surface firmly contacts the base or the bottom of the upturned sculpture. Then the difficult part - walk away and don’t fuss with it until the epoxy is cured.